Simplified mechanics

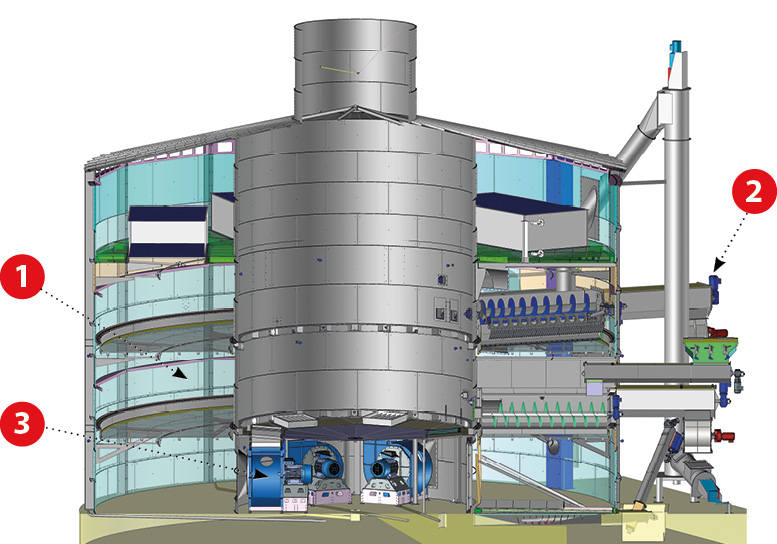

| The gap of approximately 2m between the plates makes it easy to access and move around inside the dryer, which has interior lighting. |

|

| Direct access to almost all mechanical components from the exterior. |

|

| No noise pollution thanks to the fans being located inside the dryer together with insulated external walls. |

|

Reference |

Drying |

Diameter |

Height |

Capacity |

| DO 200 | 200 m² | 13,59 m | 15 m | 9 t/h |

| DO 300 | 300 m² | 16,05 m | 15 m | 13,5 t/h |

| DO 400 | 400 m² | 19,76 m | 15 m | 18,0 t/h |

| DO 500 | 500 m² | 22,23 m | 15 m | 22,5 t/h |

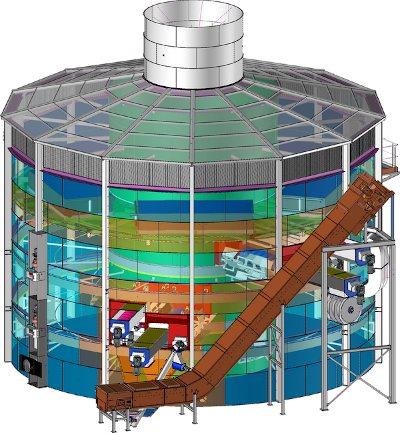

The DRYER ONE™ unitis equipped with insulating metal silo walls. The compact size and circular shape of the unit offer several advantages :

Due to its low weight, only shallow foundations are required (20cm reinforced concrete).

Simple maintenanceEssentially the DRYER ONE™ drive system requires only 2 gearmotors of few kW per rotating plate. This has several advantages : much lower electricity consumption during locomotion, simpler maintenance, silence when in use, very low risk of production incidents, ... Most testing and maintenance tasks can be carried out quickly, without generally having to stop production.

Security : reduced risk of fire

|